Product Details:

| Place of Origin: | Jiangsu China (Mainland) |

|---|---|

| Brand Name: | JIANGSU HUACHENG |

| Certification: | ISO9001 14001 BV TUV PED DNV etc |

| Model Number: | HC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5MT |

|---|---|

| Packaging Details: | Exporting package/wooden box package/Or per customers’ requirement |

| Delivery Time: | 25~35days |

| Payment Terms: | 30%T/T in advance or 100% L/C at sight |

| Supply Ability: | 8000MT/Month |

| Certificate: | PED, ISO, TUV, BV | Delivery Condition: | Annealed, Heat Treatment, Normalized, BK, BKS, BKW, NBK, GBK |

|---|---|---|---|

| Grade: | 35CrMo, 30CrMo, 26Mn5, 20Mn2B, 20CrMo | Product Name: | Truck Stabilizer Bar |

| Standard: | ASTM, DIN, EN, BS, ISO, GOST, SAE | Surface Treatment: | Galvanized, Bare |

| Technique: | Seamless | Application: | Automobile |

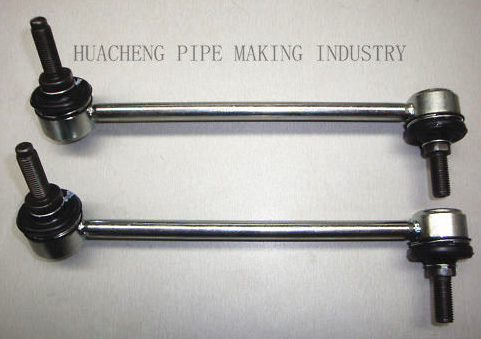

35CrMo 30CrMo Steel Truck Stabilizer Bar with PED ISO Certificate , Galvanized Stabilizer Link

Quick Detail:

Standard: ASTM / DIN / EN / BS / ISO / GOST / SAE

Grade: 20CrMo

Size:(mm)

Out Dimensions: 15.9mm

Wall Thickness : 2.6mm

Length: Fixed(6m,9m,12,24m) or normal length(5-12m)

Description:

Seamless Steel Tubes for auto stabilizer bar / auto stabilizer link / auto part / automobile components

Precision in size, Bright for the surface, high ability of mechanical performance

Stabilizer Bars:

Hollow stabilizer bars made from seamless tubes are lighter than their traditional solid counterparts and as a result these are increasing in popularity. HuaCheng is an established supplier of seamless tubes to some of the largest manufacturers of stabilizer bars globally. We have worked closely with our customers to develop special grades of steels that are cost effective and yet meet the high fatigue failure norms required of these tubes.

Standard: ASTM / DIN / EN / BS / ISO / GOST / SAE

STEEL GRADE: 20Mn2B, 26Mn5, 30CrMo/4130, 20CrMo, 35CrMo, 30CrMo, 30CrMo 4130

Surface treatments:

1. Bare Tube (No coating): Bright and smooth, Surface Roughness both inner and outer surface

0.2Ra Maximum for special requirement

2. Surface Coating

A. Silver galvanized

B. Yellow galvanized

C. Olive green coated

Layer thickness: 8-20um, Salty Spray Test: 48-150 hours

3. Black phosphate

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength, Yield Strength,Elongation, Flaring, Flattening, Bending, Hardness, Impact Test),Surface and Dimension Test,Nodestructive Test, Hydrostatic Test.

Packing:

Each tube is oiled, internally as well as externally, and then packed into hexagonal bundles. This ensures that the tubes are corrosion protected and that they retain their straightness during transport. Upon request we can provide end caps and also wrap the bundles in LDPE sheets

Main Applications:

Mainly used for Automotive fields auto stabilizer bar / auto stabilizer link / auto part / automobile components / For car, train, tank, truck etc.

Relative Industries and Applications:

• Air bag canisters

• Front wheel drive shafts

• Anti-roll bars

• Piston pins

• Collapsible steering columns

• Steering linkages

• Transmission shafts or Propeller shafts

• Trailer axles

• Stub axles

• Gear shafts

• Common rails (Diesel engines)

• Clutch parts

• CV cages

Final supply conditions:

|

Designation |

Symbol |

Description |

|

Cold finished (hard) |

BK |

Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

|

Cold finished (soft) |

BKW |

The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

|

Cold finished and stress-relieved |

BKS |

Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

|

Annealed |

GBK |

The last cold forming process is followed by annealing in a controlled atmosphere. |

|

Normalized |

NBK |

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Competitive Advantage:

Huacheng Industry Pipe Making Corporation

Asia Leading Steel Pipe & Tube Manufacturer with more than 250,000Tons/Year, >60% shipped to more than 35 Countries.We aims at manufacturing quality pipes & tubes with reasonable and competitive price, good quality for our global customers.